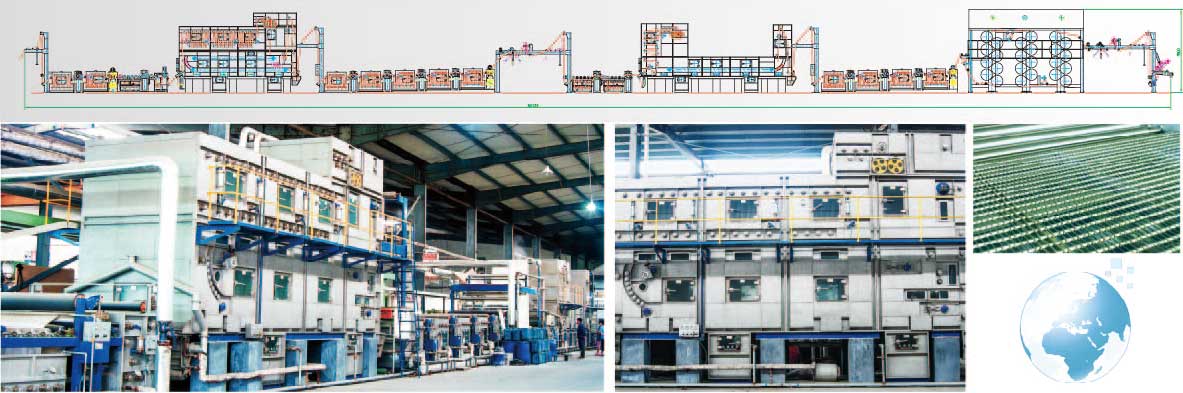

一、用途

本机供棉、涤、麻及混纺织物进行平幅连续式退浆、煮练、漂白、使织物具有良好的毛效、白度等,为产品后道工序中的染色、印花的质量提供保证。

二、技术特性

1、积木式结构,可根据不同的产品和工艺要求,选择组合机器流程。

2、公称幅宽:1800-3600mm。

3、导布辊棍径:150-200mm。

4、交流变频传动,机器车速:10-80m/min;15-100m/min。

5、气蒸箱形式:单层网片蒸箱、单层复合蒸箱、双层复合蒸箱、R-box、敞开式履带床。

6、不锈钢网片结构,承重强度高、透芯彻底,避免横档印,保证均匀一致。

7、可预热后堆叠反应,也可紧式气蒸后直接出布,免堆叠。

8、预热区采用粗导辊,多点共源分组变频传动,不易产生皱条,适应细支高密弹力织物的特别需要。

9、进布气封,出布能水封、气封或两用,外表面保温节能,面板喷丸。

10、可采用高给液装置,使织物带液充分,化学品能均匀参透,保证高质量的煮练效果

1. Application

This machine is used for desizing, boiling and bleaching the fabrics of cotton, hemp and their blends, so as to enhance the whiteness and capillary effect, thus the quality of the fabric can meet the requirement of the sequence process.

2. Technical featues

(1) Use the building block structure; you can combine the production lines according to the requirements of different products and technologies.

(2) Nominal width:1800-3600mm.

(3) Diameter of teitch roller:150-200mm.

(4) ACfrequency conversion transmission, machine speed:10-80m/minute;15-100 m/minute.

(5) Steaming box structure; single layer grid sheet steaming box, single layer cmplex steaming box, double layer complex steaming box,R-box, open crawler.

(6) Stainless steel grid structure, with high load bearing strength, to make the saturated steam easy to reach, ensures the consistency of the scouring and bleaching and avoids the crosspiece printing.

(7) Enough heat to achieve the fabric's equable effect of chemical reaction upon heating, so as to avoid the overstocking of fabrics.

(8) In the pre-heating zone, use a big twitch roller, multi-point, grouped frequency conversion transmission, so as to ensure less crumples and be suitable for high-density elastic fabrics.

(9) Adopt the vapor lock in the fabric-in process; adopt both the hydroseal and the vapor lockin the fabric-out process, and the outside surface fo the machine is heat preserving and energy saving.

(10) High liquid supply system can make fabrics carry enough liquid, so as to ensure the symmetrical penetration of chemicals and hence to ensure the high-quality boiling.